Crafting Precision: The Role of Flat Laser Cutting in Modern Manufacturing

Key Takeaways

- Flat laser cutting is a versatile and precise method prevalent in modern manufacturing.

- Beneficial in numerous industries, its applications range from automotive to aerospace.

- The technology offers precision, efficiency, and cost-effectiveness.

Introduction to Flat Laser Cutting

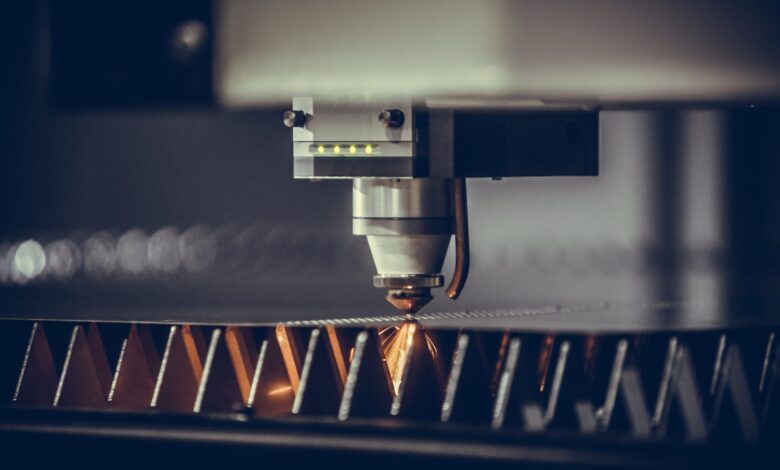

In today’s fast-paced world of innovation, flat laser cutting is a pivotal component in manufacturing, offering precision and versatility that has not been heard of in previous decades. This modern method employs a highly concentrated beam of light to cut materials accurately, dramatically reducing waste and maximizing detail and accuracy. This technology remains indispensable to manufacturers seeking precision, whether for complex industrial tasks or more minor, more straightforward projects.

Over the past few decades, incredible advancements in laser cutting technology have rapidly established it as a favored choice amongst industries looking to produce exact, efficient, and pristine components. Organizations worldwide have recognized the unmatched benefits of integrating flat laser cutting into their production processes, yielding superior outcomes and consistency.

Technology Behind Laser Cutting

The essence of flat laser cutting lies in the remarkable power of its lasers. These lasers cut through various materials with incredible precision by harnessing intensely focused light energy. It’s no wonder that regions such as laser cutting Manitoba are quick to embrace such advanced techniques for their production needs, ensuring they maintain rigorous standards of both quality and efficiency. The most widely used lasers include CO2, fiber, and crystal, each meticulously selected based on specific material characteristics and intended applications. These devices can produce results that are not only precise but also repeatable, a critical factor in mass manufacturing. Technological innovations continuously enhance these lasers, guaranteeing more efficient output and amplified precision. This ongoing progression is vividly chronicled in numerous publications, such as advancements in laser technology, which signals further transformative impacts across multiple industries.

Applications in Key Industries

Flat laser cutting’s incredible versatility is showcased across various industry applications, validating its universal appeal. In the automotive sector, laser cutting ensures every car component adheres to exact and uncompromising standards, enhancing vehicle safety and performance. Heavyweights in the aerospace sector depend on precision laser cutting to create essential elements expected to withstand extreme conditions in rigorous environments, thus ensuring reliability and durability.

Furthermore, electronics manufacturers utilize the method to produce complex and intricate parts crucial for device functionality, where precision is not only necessary but essential. The medical industry also benefits significantly from using laser cutting to manufacture precise surgical instruments and life-critical devices that adhere to stringent quality protocols and standards. The diverse applicability of laser cutting underscores its essential role in delivering cutting-edge results across many sectors.

Advantages Over Traditional Methods

The multitude of benefits that flat laser cutting provides compared to traditional manufacturing methods cannot be overstated. Its high precision leads to unparalleled accuracy that eliminates the need for secondary processing stages, significantly reducing time and resources. The non-contact nature of laser processing ensures less wear and tear on tools, prolonging machine life and reducing overall maintenance costs.

Flat laser cutting also enhances production cycles’ speed and efficiently handles complex design requirements, making it a highly cost-effective option for manufacturers looking to optimize quality. These benefits position laser cutting as the go-to method for countless manufacturers aiming for optimal harmony between perfection and cost-consciousness.

Future Trends in Laser Technology

As the manufacturing landscape evolves, so do the prospects for laser-cutting innovations. Prominent future trends include the greater integration of automated processes and AI, promising heightened precision and boosted efficiency. Furthermore, researchers and innovators are concentrating on exploring new laser-cutting applications in new materials, effectively expanding its capabilities beyond current boundaries.

These forward-looking innovations are set to redefine the parameters of how industries utilize laser technology, presenting solutions that are smarter, more efficient, environmentally sustainable, and conscious.

Considerations for Using Laser Cutting

While laser cutting offers substantial benefits, certain factors require careful consideration to optimize outcomes. Choosing the correct type of laser, based on material type and thickness, is critical in determining the appropriate settings for ensuring seamless cuts. Additionally, safeguarding the operation of laser systems is vital, mandating strict safety measures to protect against laser beam exposure hazards.

Regular maintenance and calibration of the cutting apparatus are necessary to preserve and maintain accuracy and peak performance levels, guaranteeing the technology’s sustainability and longevity in routine and demanding operations.

Real-World Examples

The practical application of flat laser cutting extends to numerous exemplary projects globally. Laser-cutting techniques create lightweight automotive frames, ensuring components that offer unparalleled strength and satisfactory efficiency metrics. Meanwhile, custom jewelry pieces greatly benefit from the precision and refinement options that laser technology affords, allowing for deeper, more intricate designs.

Globally, industries utilize laser-cutting technologies, achieving tangible breakthroughs that harmonize design elegance with practical functionality. These examples decisively emphasize the transformative impact of laser cutting technology within the manufacturing sector, boding well for future advancements and opportunities.